Design and manufacture of pneumatic molds

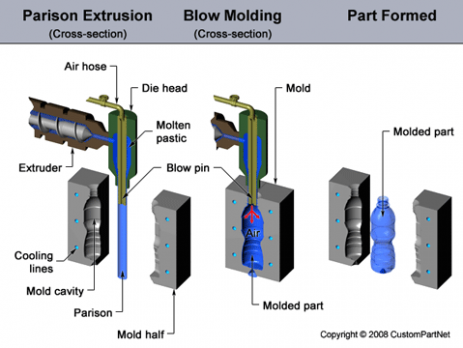

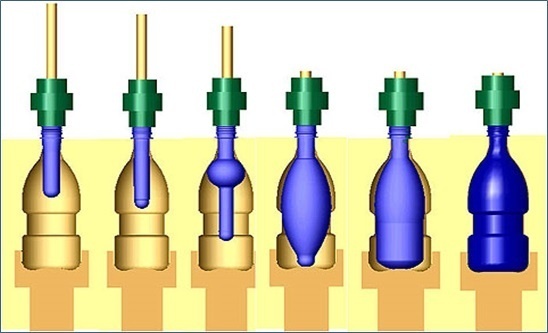

One of the methods of producing hollow plastic parts such as containers and bottles is the blue molding method or the use of pneumatic molds. In this method, mainly in two ways, the use of primary preform or hot extrusion of materials and bottle formation is done by using wind blowing.

Examples of extruded blow molding are a variety of shampoo containers or toilet liquid or a variety of gallons.

Examples of blow molding using raw materials produced (by injection method) or preform of beverage containers.

Sample of parts produced in this way: Ladies mascara bottle! Sterile eye drops bottle and

*** To order and see different types of pneumatic molds, you can see our pneumatic molds. Also balloon machines that are all made by PartPat ***

We are a manufacturer of all kinds of PET and polyethylene molds, as well as free advice on buying molds or machines

Contact the following numbers for more information

021-77007827

021-77007828

021-77318511

Pneumatic molding with pulling

In this method, the molded plastic (melt) is injected into the mold by extrusion and is pulled before the wind is blown into the mold, which makes the side wall thinner, more durable and shiny, and the top and bottom of the bottle. It is created with less shine and more thickness and reduces the permeability to CO2 gas and moisture in it.

PVC bottles are produced using this method, which is used in the packaging of edible oils, fruit juices and concentrates.

Pneumatic injection molding is used to produce large quantities of hollow objects. Its main applications are in the production of bottles, juice containers and other small empty containers. Injection molding is used in comparison with extrusion molding to produce high quality visual and dimensional bottles. This process is ideal for producing both narrow and wide-mouthed containers and produces them completely and without flash. Ends.

Part Pet Engineering Group has been active in the field of design and manufacture of pneumatic molds, production of pneumatic parts, design and manufacture of plastic parts and plastic molds, design and manufacture of rubber molds and production of rubber parts, and design and manufacture of various industrial molds.