What is granule? How is granule production?

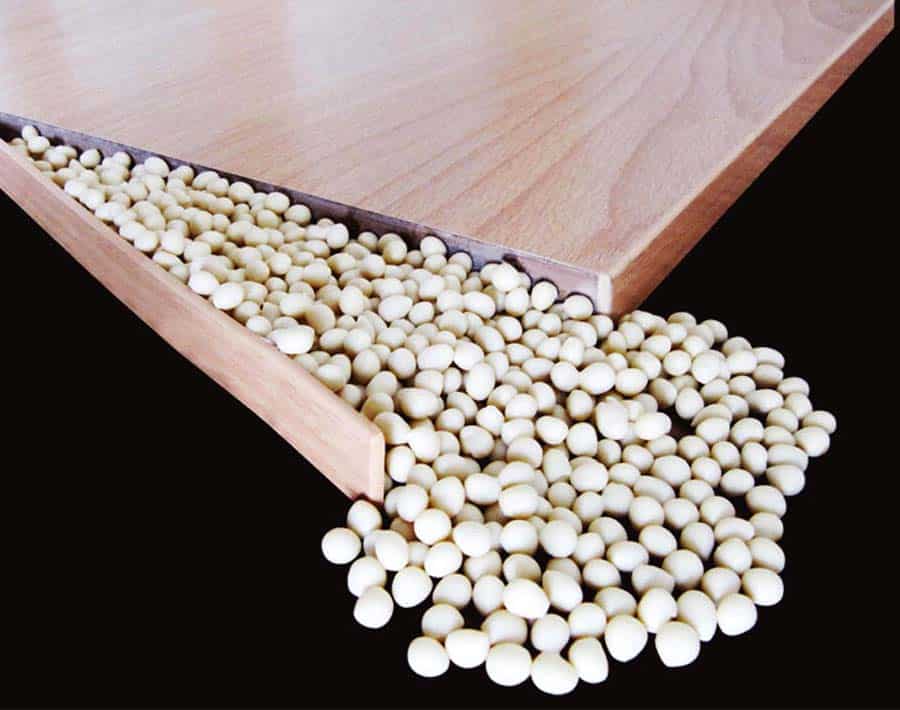

Granules are not the name of a specific polymer. A type of polymer obtained in petrochemicals that is in the form of granules and must be melted and shaped for applications is called granules.

In fact, when the polymer is produced, it is melted in the extruder (something like a meat grinder) and at the head of the extruder, a cutter or something similar cuts the output polymer regularly and granules are produced.

All polymeric materials can be granulated depending on the application and the degree of viscosity and other factors such as the type of polymerization and.. However, if the polymerization conditions and other factors are complex, the polymer is produced as a powder or solution or..

The main purpose of producing a polymer is to obtain a material with the desired properties. Obtaining these properties and controlling them during the polymer process depends on many factors such as temperature, pressure, catalyst and…. The polymer that was first melted and shaped certainly has better properties than recycled polymers that have been melted several times. Some polymers retain their properties after repeated melting and reshaping. But some of them, such as PVC polyvinyl chloride, which are widely used in door and window profiles, tablecloths and sheets, cables, appliances, etc., lose their properties after recycling.

Using the produced granules, they produce rubber grain flooring.

One of the most widespread and important parts of the plastics industry is the recycling of plastic waste into reusable granules for other producers, because the raw materials of this industry are worn and stored tires in the regions of the country, which are abundant in Iran. Are found and several thousand tons are added to their volume annually. Also, the product produced by these machines, rubber powder and standard rubber granules, the raw material of many industries such as the production of various types of flooring, various reinforcements and alternatives in paints, asphalt, concrete, as well as the main fuel of the furnace, rubber raw material And و and has many applications at home and abroad.

Provision of a uniform and quality granule that does not reduce the quality of the product and does not have process and quality problems for the consumer is always one of the most important concerns of recycling industry activists.

Granule production

Plastic granules are small balls of plastic that are poured into various plastic forming machines and turned into different types of parts.

The system of plastic forming machines (including all kinds of extrusion and injection lines, etc.) is made in such a way that it is better for their raw materials to be in the form of small plastic balls.

Recycled plastics that have been milled and have sheet shapes or sharp corners can not be easily used in the inlet hoppers of these devices, and of course the mixing time is always a non-uniform composition with other materials due to their non-uniform size.

Therefore, consumers of these materials prefer their purchased materials as new raw materials in the form of granules or the same small plastic balls, which is done by a line called the granule production line.

These lines work in two ways:

First method: filament granule production lines

The production of filament granules, which are easier to manufacture and are commonly used in Iran, is a method in which the plastic, after melting in the extruder and passing through metal filters, becomes strands of molten plastic, and after They are passed through a pool of water into a small mill and dried after being crushed.

This method is simple, but the granules produced with it are not similar to the granules of new raw materials and have sharp corners and plastic chips.

The line itself is not stable and the strings are constantly cut and requires a full time operator.

Second method: dry granule production lines

In this method, the crushed plastics, after melting in the extruder and passing through the strainer, are taken out of small holes and in the same way the melt is cut by a blade that cuts at high speed. It is sucked at the same time by a sucker and cooled and dried by passing through tubular passages. Then, by entering a larger tank, the pressure drops and as a result of this pressure drop, the heavier granules fall to the bottom of the tank and air comes out from above it.

The construction of its machines requires higher accuracy and remote controls must be used in different parts of it. The overall price of the line is higher, but the granules produced are very similar to the granules purchased from petrochemicals, and the production line itself is completely stable during operation. .

Granulating machine – extruder

Extrusion is the final step in many plastic recycling lines. Extractors usually receive uniform materials. If the recycling line does not work properly during the cleaning and drying process, the extractor will not work properly either. This usually happens at other stages of the recycling line.

An extruder must have these characteristics in all stages:

A good drain with a powerful vacuum pump to increase the effect of the bite, if the discharger is two, the result is better.

A strong and large screen changer because sometimes, if the material is not well washed, and this will happen, and the product has to be taken anyway, a big screen changer will help a lot.

Single-screw extruders are the most commonly used. Single-screw extruders are just a pump. Single-screw extractors are easier to implement, difficult to disassemble, and cheaper than other types. In single-screw extractors, processing is high and maintenance costs are low.

Hazardous and chemical gases in the materials used are eliminated by adsorption in the vacuum system, and the gas generated after this stage is cleaned of any dangerous elements in accordance with European standards and taking into account human health.

Depending on the material used, the extractor operates with a capacity of about 1200-100 kg per hour.