What is an injection machine?

One of the most convenient, widely used and important methods for forming polymers (polymers) is the use of injection molding machine. After the emergence and development of plastics, efforts began to build devices by which plastic materials could be easily shaped to their desired shape, leading to the invention of the injection molding machine. But before making modern injection machines today, it was very difficult to shape plastics. At first, molds were prepared with great care and effort and were installed in hand clamps and a cylinder with a piston was installed on it and around The cylinder was heated with flames, and after the material melted, the material inside the cylinder was injected into the mold by the pressure of the pulley above the piston, and after the material inside the mold had cooled, the clamps were opened and the pieces of the mold were opened. They separated and produced the product, and all these steps were done by hand, until modern injection machines were produced. The first primitive injection machine was built in the United States in 1872, and the first advanced screw injection machine was registered in the United States in 1946 by James Watson. The main task of the injection molding machine is to convert solid plastic materials (fine grains or polymer granules) into fluid and smooth plastic and transfer it to the mold so that the fluid materials are always ready to be injected into the mold.

Types of injection machines:

1. Vertical

2. Horizontal

Types of injection machines in terms of material transfer system:

1. Piston

2. Mardoni (screw)

Types of injection machines in the direction of moving the moving plate:

1. Arm devices

2. Jackie devices

Different parts of injection machine:

1. Injection section

2. Molding part

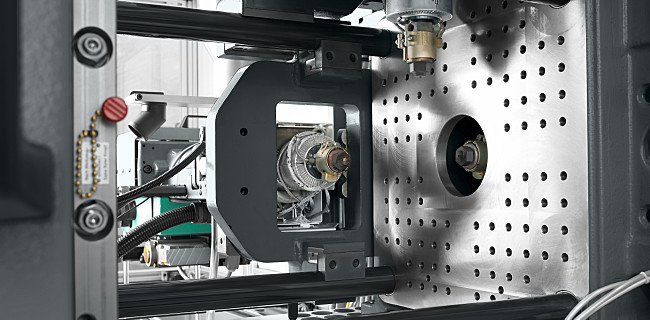

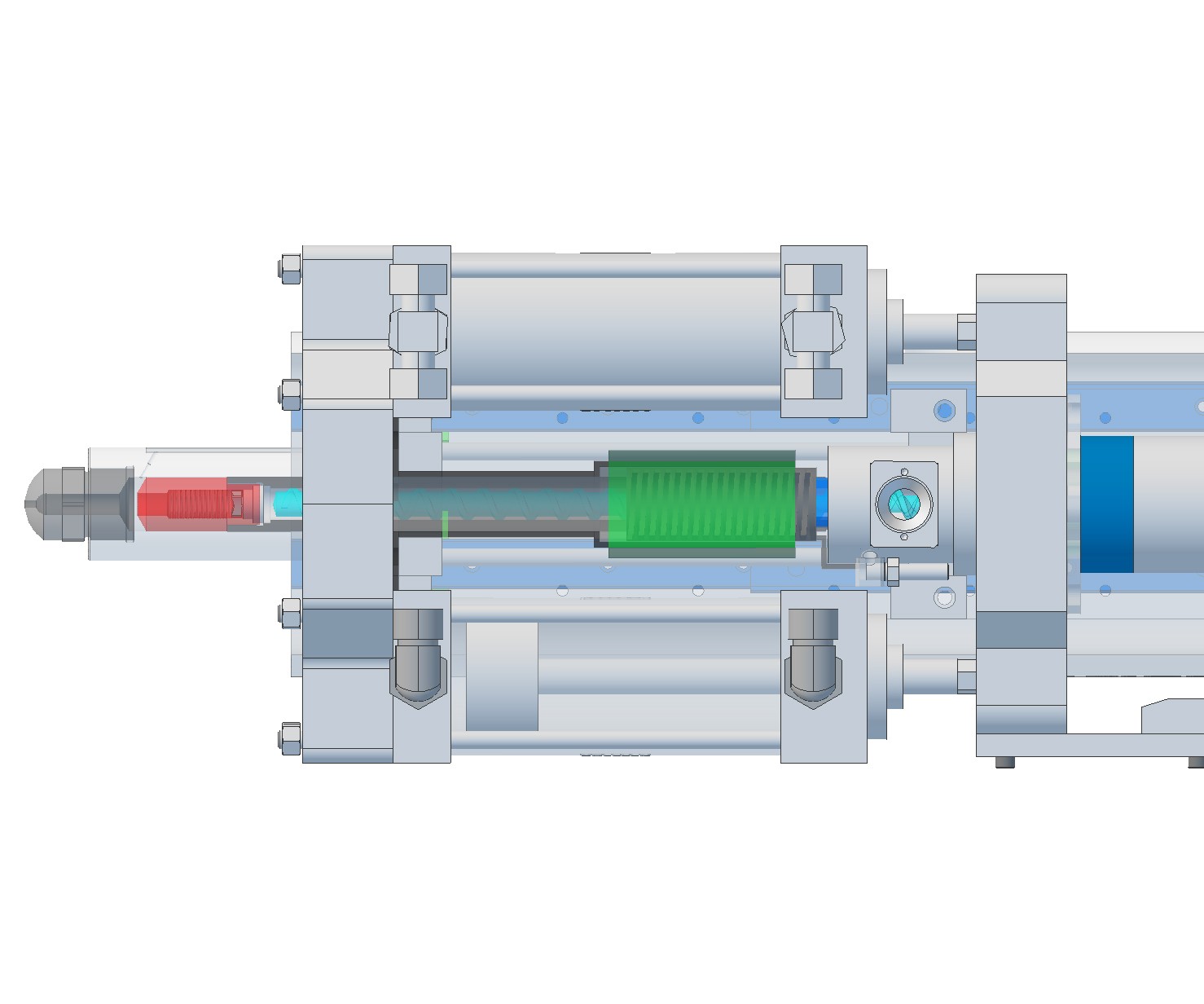

Injection unit

In this unit, the operation of melting, mixing and injecting materials is performed. In this way, first the plastic material is poured into the hopper (Hopper) and gradually passes from the funnel into the cylinder (Barrel) and is pushed forward by rotating the screw (Screw). The cylinder shell is completely heated by electric heaters (Heater) located along the outer wall of the cylinder and reaches the front of the cylinder. The spiral rotates around itself to perform the act of picking (like a meat grinder) and has a horizontal forward motion. At the same time, as the helix moves forward, the material that has already accumulated at the cylinder head and behind the valve is injected into the mold due to the helix pressure. After a certain period of time determined by the user of the device, by injecting the pressure behind the helix and resuming the extraction, the injection cylinder returns to the back.

Different components of injection part:

1. Spiral

2. Nozzle

3. Injection cylinder

4. Material funnel

5. Heater

6. Thermometer

7. Thermocouple

Mold Clamping Unit

The mold holder is a large container on which the mold and its components are mounted. The molding unit has 2 main parts: fixed part and movable part

The power of an injection machine is expressed in terms of the tonnage of the force of the two jaws holding the mold (maximum force applied to the back of the movable plate). In general, two systems are used in injection molding machines to create pressure behind the mold: mechanical system and hydraulic system. The mold is connected to the center of the fixed part on one side and to the center of the moving part on the other side, and because the mold is always opened from the middle to eject the produced part, when the said plate is opened, it takes half of the mold with it. It pulls back. This makes the production part jump out, then the moving plate returns to its place and the mold is closed to perform the re-injection operation. After closing the mold and straightening the arms by creating pressure (at least more than the injection pressure), it keeps the molten material inside the injection mold, because if the pressure behind the mold is less than the injection pressure, the seam between the two plates of the mold opens and the material The plastic falls out or an outer circle is formed of the piece produced by the pleat.